Downing

Well-Known Member

Well guys, I gotta say that I'm really liking where these CNC methods are taking me.

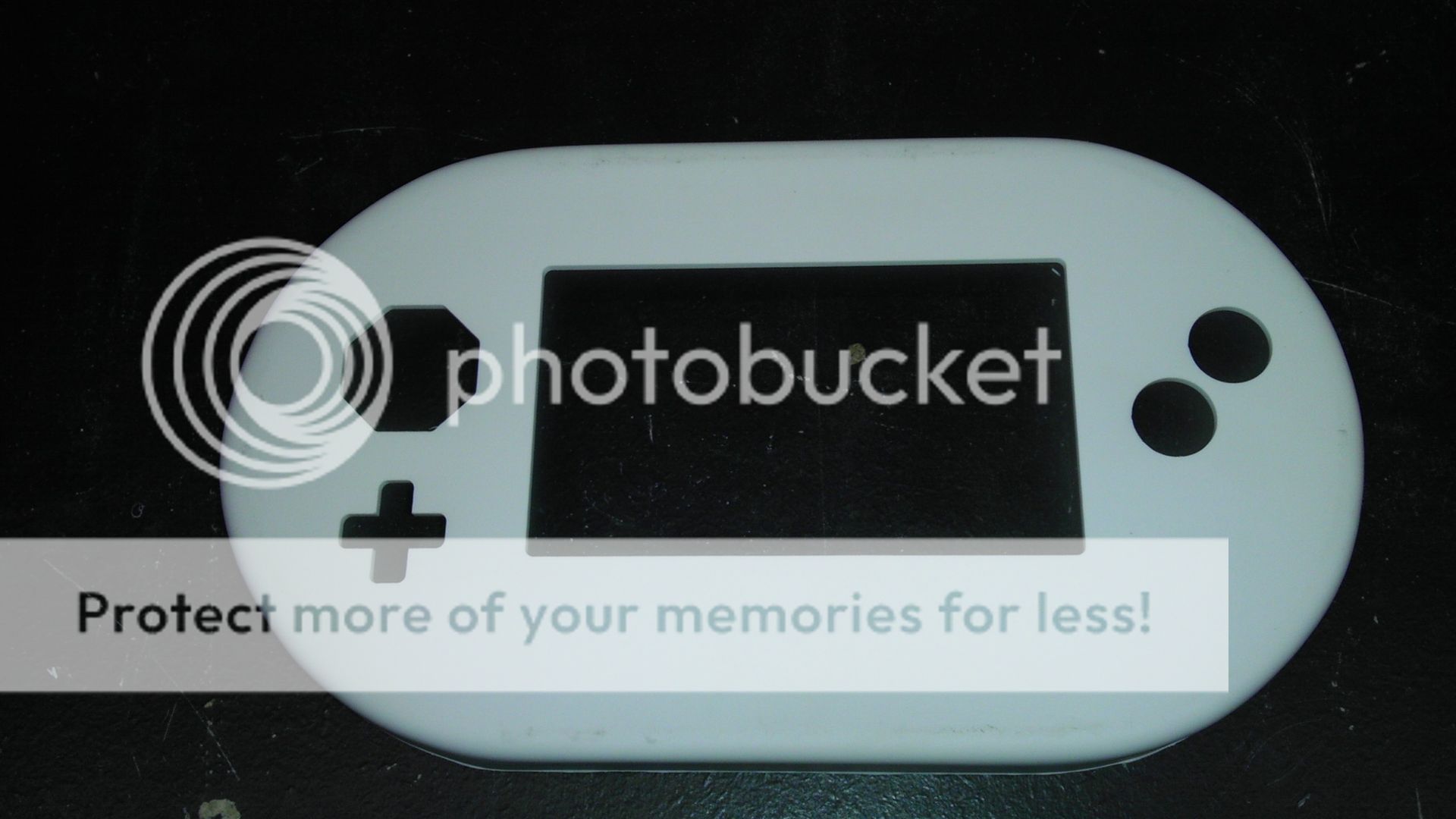

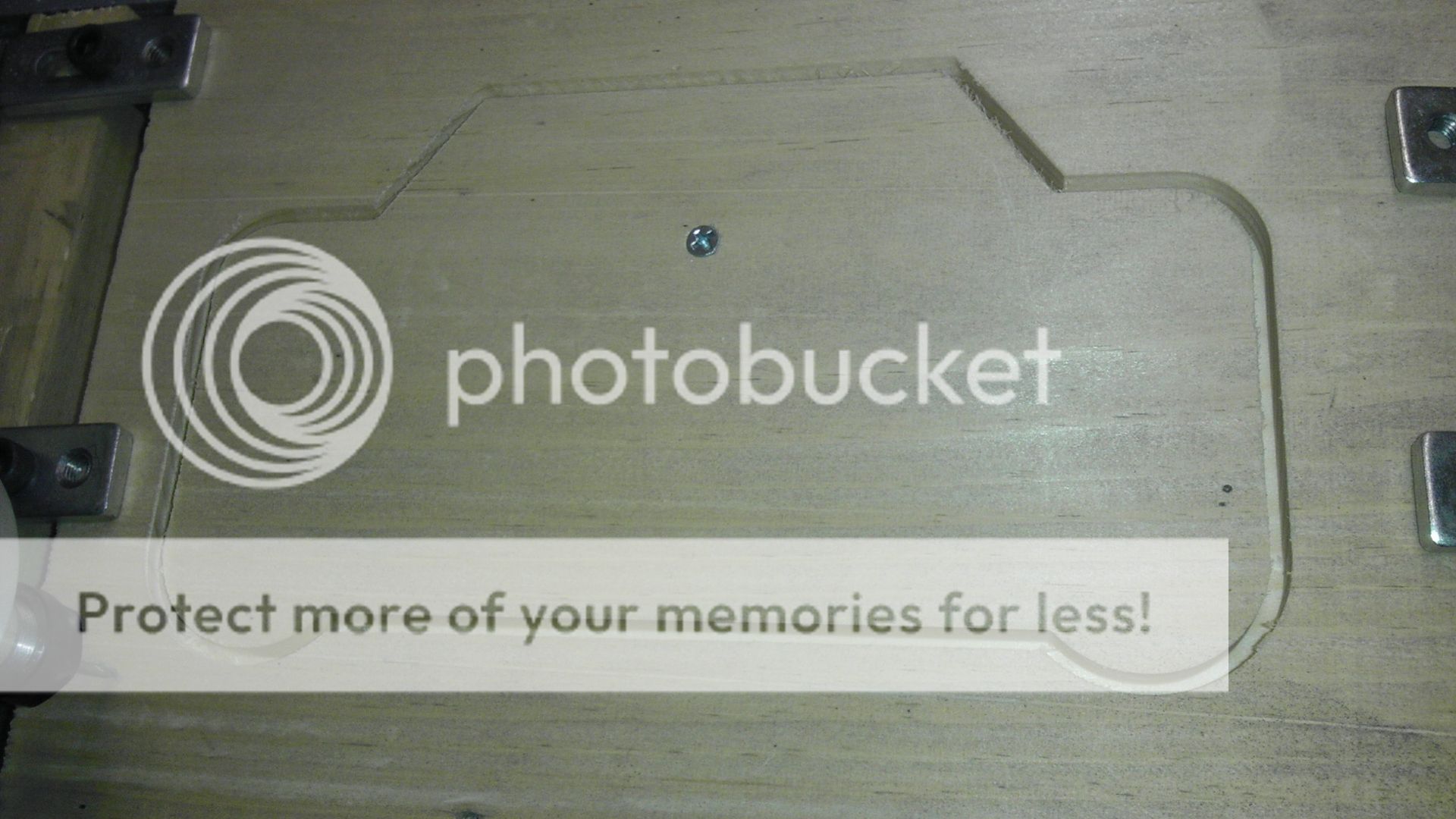

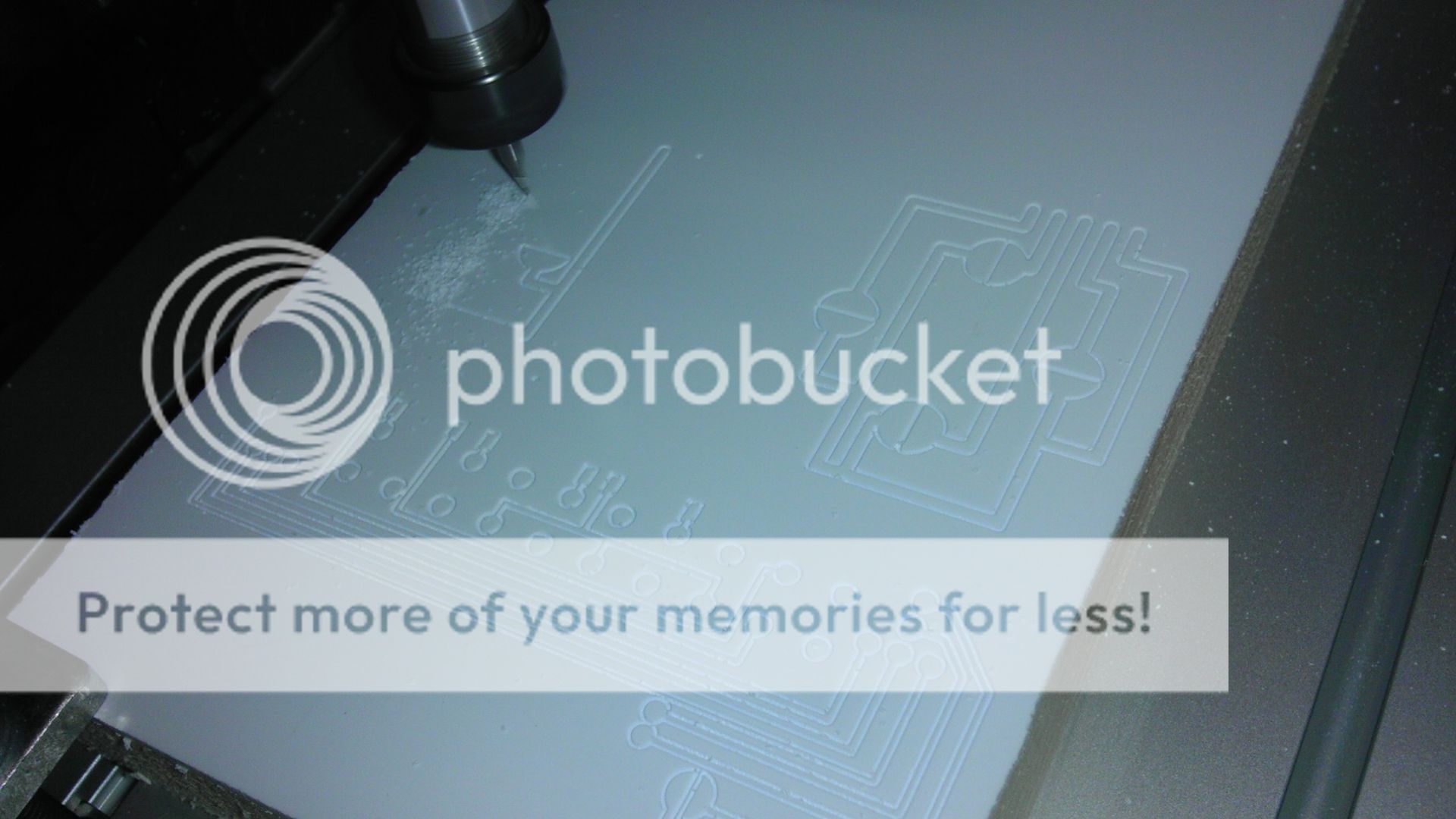

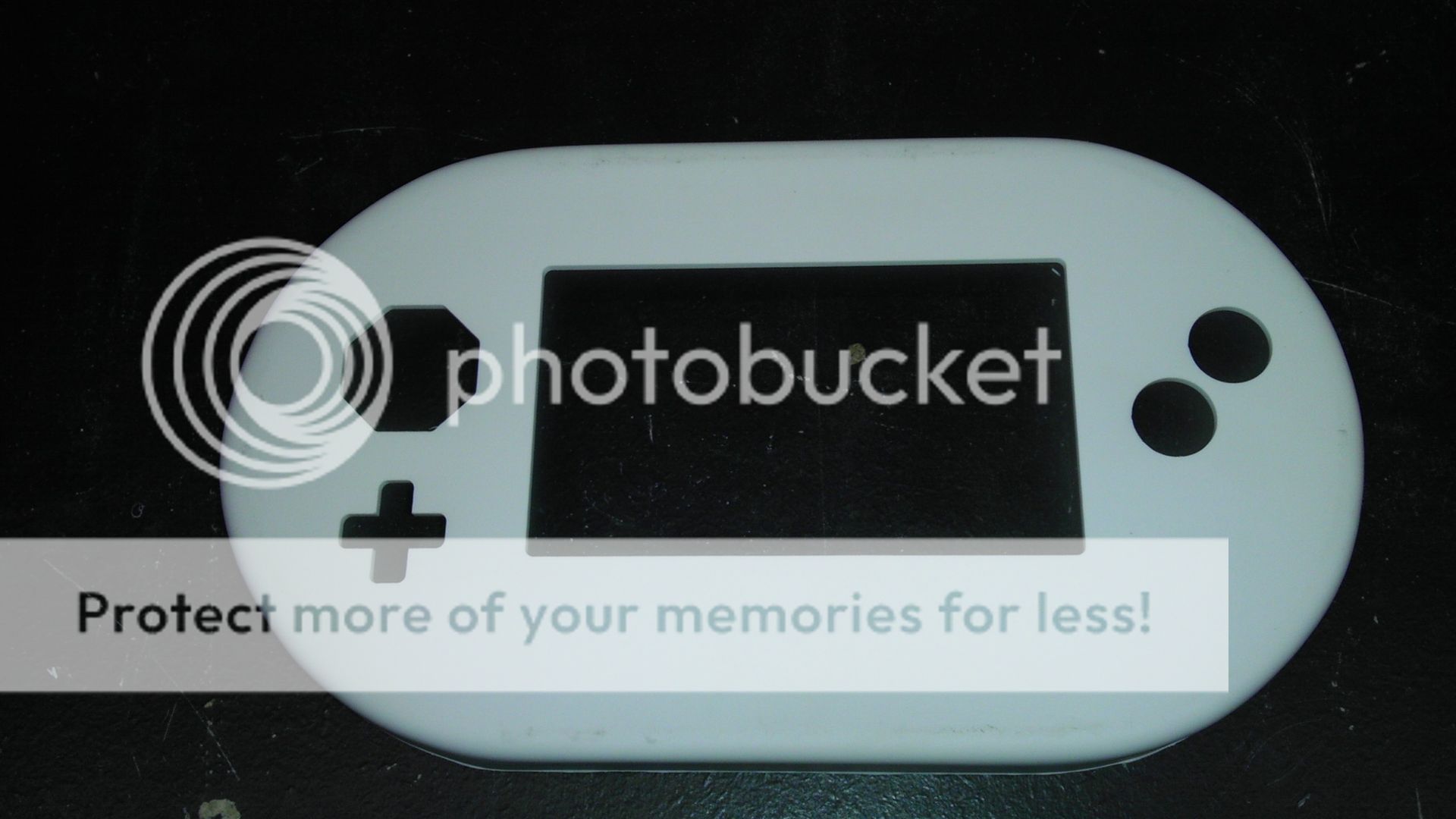

The video below shows the machine in action on a copy of the case I made for Evil Nod's N64 project. This was not built for any system in particular, just a test to see how it would work for cutting out screen, d-pad, control stick and buttons.

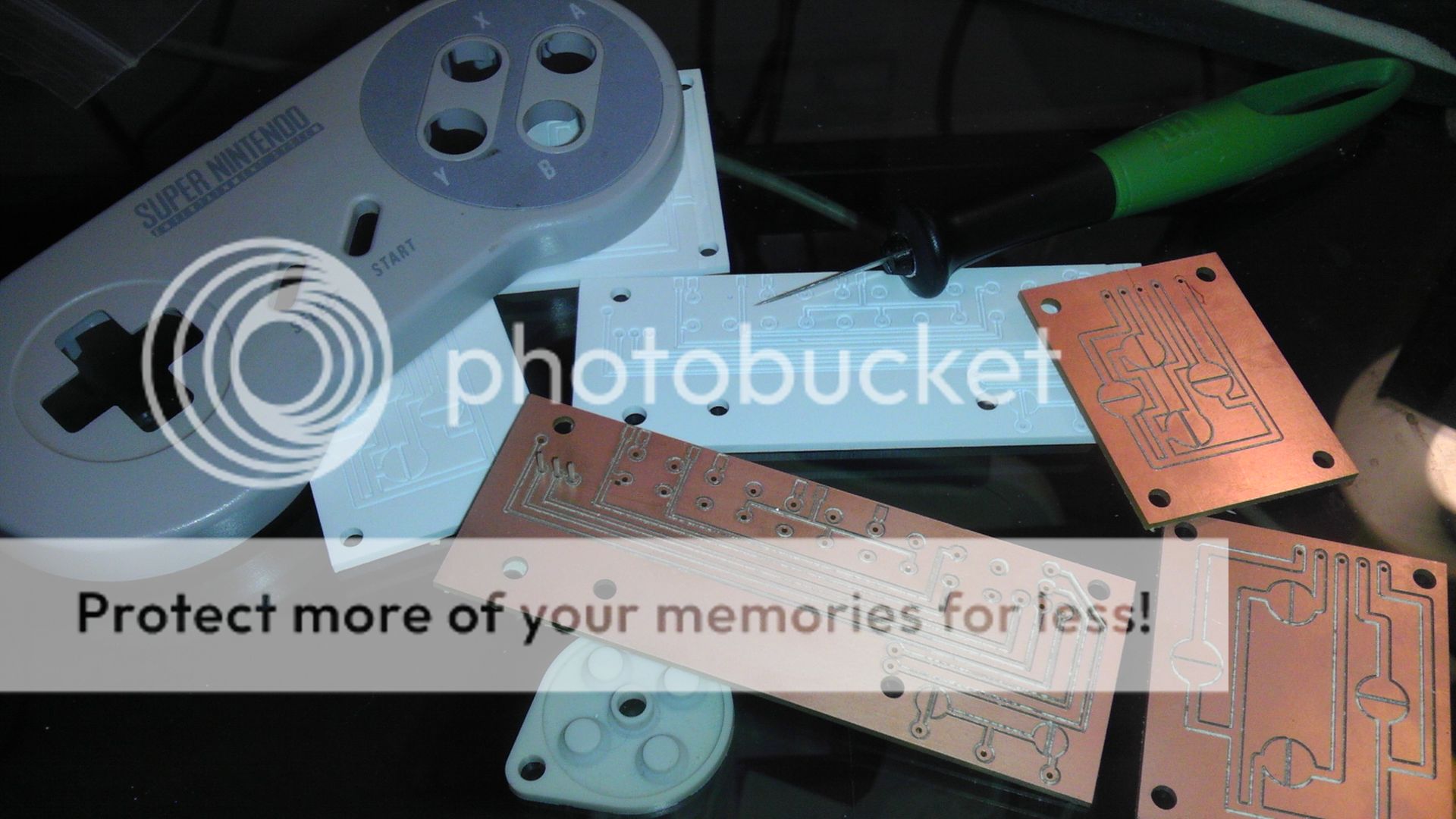

I think what I'm going to do is start putting component dimensions into the CAD software and saving them individually under manufacture name and part, that way I can simply cut and past the components into place in any number of custom arrangements. Same deal for the PCB's underneath them. Now with the ability to cut those, I can also make the trace/pad layout and cut and past that into a bigger PCB and then just connect the traces once it's in position.

I like I like I like!!!

But you can see in the pics below how clean the cuts are! No more Dremel Fiber disc cuts, then filing, then filling then sanding. All this time is being redone into the design of the casing, but like I said, once I get a hand full of components into CAD, it will be as easy as cut an paste!

The video below shows the machine in action on a copy of the case I made for Evil Nod's N64 project. This was not built for any system in particular, just a test to see how it would work for cutting out screen, d-pad, control stick and buttons.

I think what I'm going to do is start putting component dimensions into the CAD software and saving them individually under manufacture name and part, that way I can simply cut and past the components into place in any number of custom arrangements. Same deal for the PCB's underneath them. Now with the ability to cut those, I can also make the trace/pad layout and cut and past that into a bigger PCB and then just connect the traces once it's in position.

I like I like I like!!!

But you can see in the pics below how clean the cuts are! No more Dremel Fiber disc cuts, then filing, then filling then sanding. All this time is being redone into the design of the casing, but like I said, once I get a hand full of components into CAD, it will be as easy as cut an paste!