So, I have been screwing around with this pretty cheap 3d printer. Designed for bringing 3d printing to the consumer at an affordable price, with a large build area.

It has been a long and adventurous journey, but I have done much to this printer to get it functional enough to give me some decent prints. At first it was just to fix the sagging issues, but the hotend that came with the Dang thing made me pull my hair out for a long time. I bought a clone e3d lite 6, got the wrong size for what I had, did a mod to it, figured some things out that made sense but didn't really give great results. Bought a better clone, works better, looking into getting an all metal hotend especially since I am running PETG filament. I, also, bought the heated bed upgrade that I probably shouldn't have bought. I have some ideas, and will be showing some awesome things I found doing some more research.

Anyway, on to the photos so the machine and it running. Not all photos show up to date mods unless specified.

First prints of some x gantry mods, as you can see the first one didn't turn out for flax.

This was actually a good print that was going just fine until windows decided it was time to update... so windows restarted even though I had a print running. But as you can see print quality got way better.

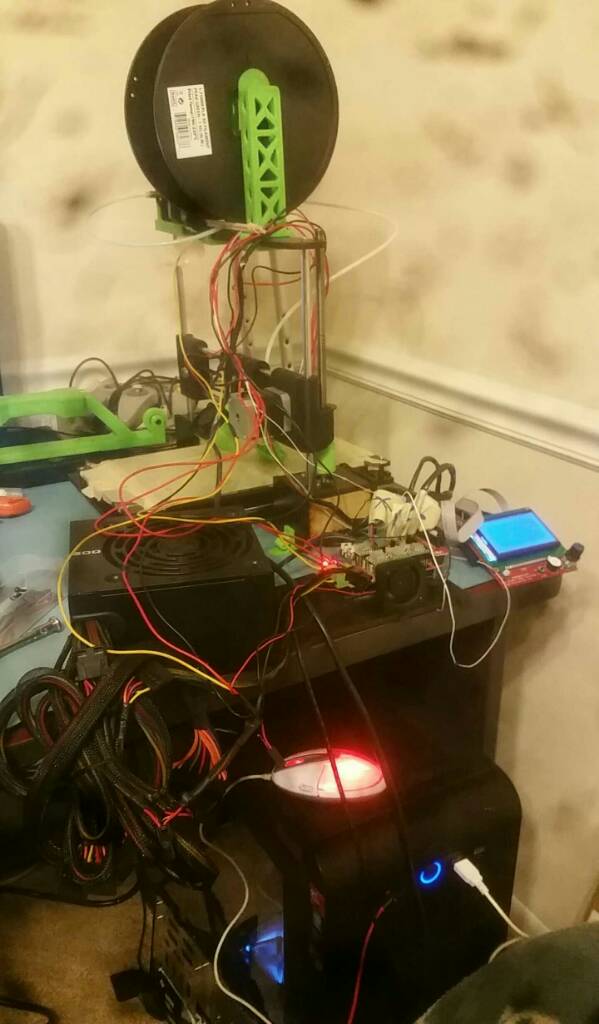

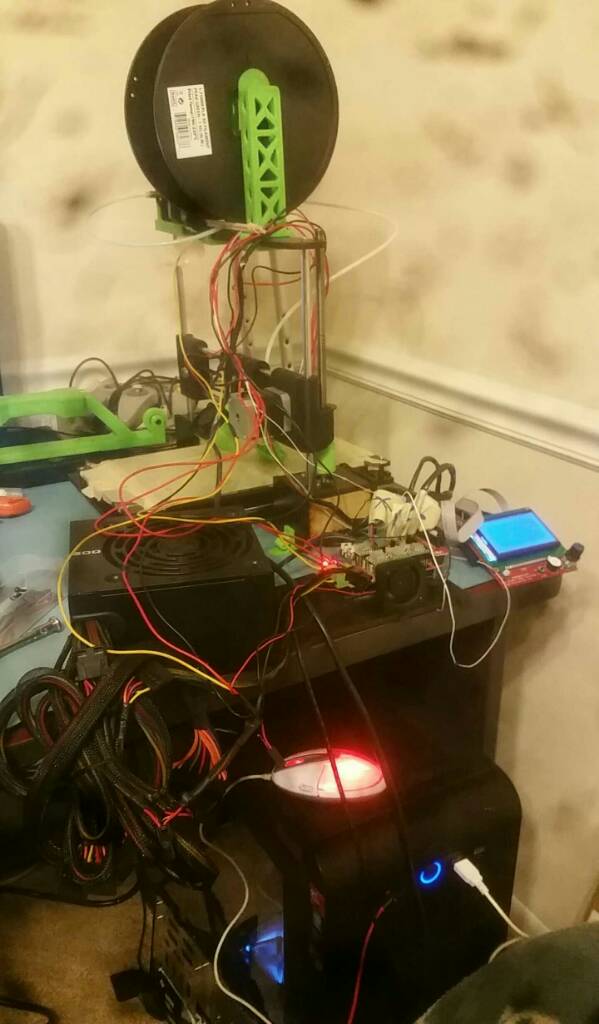

My mess of wires that needs to be contained, the anti sag mods in the back.

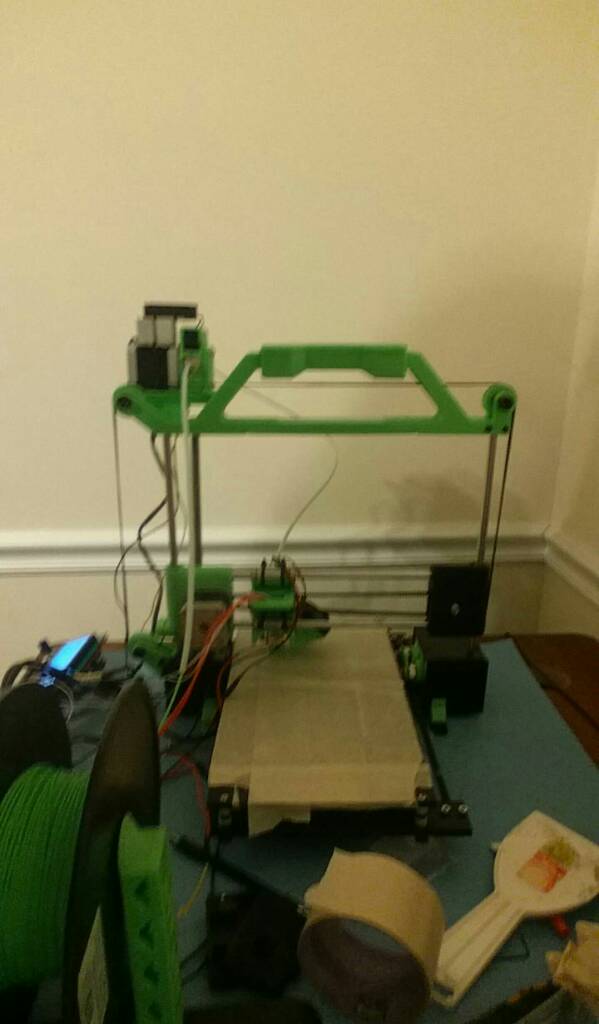

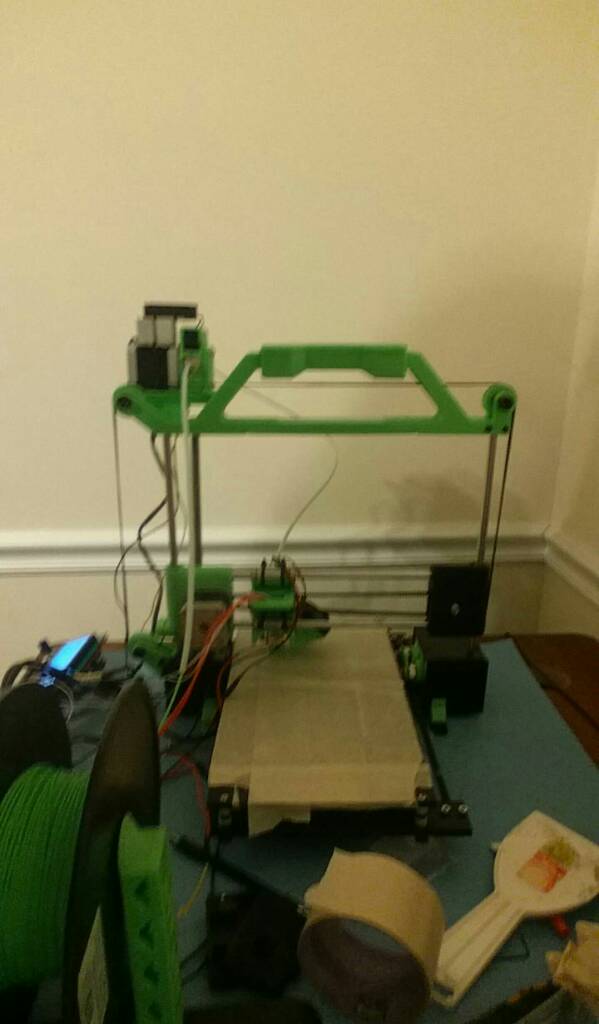

This is actually the most recent setup before I moved, and that stand I have the cold end of the extruder on broke off, so I glued part of it to the top center of the handle. You can also see that with that mod installed the x gantry sits very level. Now it's not 100% level, but within a couple degrees by a pretty good guess. I just used a regular bubble style level.

One of my early prints, it curled up a bit, I am in need of heating it up to flatten it out and paint it, and print the feet for it. It's for my girlfriend. You can see all the bad parts of it but for the most part it's pretty decent.

This is actually exactly how it's setup now except it has the heated bed installed. No shot of that yet. Also, because of the windows problem I decided to go headless and install an lcd with an sd card reader on it. That gave me a great reason to flash a new firmware set to the arduino mega board, calibrate to near perfection.

Here are some things I have printed for fun and calibration. So from what I can show its not doing too bad. I still have some things I want to print for it and reprint. I really want to print a box to enclose the electronics with the power all in one.

That's it for now. More to come soon once the work area had come together 100%

It has been a long and adventurous journey, but I have done much to this printer to get it functional enough to give me some decent prints. At first it was just to fix the sagging issues, but the hotend that came with the Dang thing made me pull my hair out for a long time. I bought a clone e3d lite 6, got the wrong size for what I had, did a mod to it, figured some things out that made sense but didn't really give great results. Bought a better clone, works better, looking into getting an all metal hotend especially since I am running PETG filament. I, also, bought the heated bed upgrade that I probably shouldn't have bought. I have some ideas, and will be showing some awesome things I found doing some more research.

Anyway, on to the photos so the machine and it running. Not all photos show up to date mods unless specified.

First prints of some x gantry mods, as you can see the first one didn't turn out for flax.

This was actually a good print that was going just fine until windows decided it was time to update... so windows restarted even though I had a print running. But as you can see print quality got way better.

My mess of wires that needs to be contained, the anti sag mods in the back.

This is actually the most recent setup before I moved, and that stand I have the cold end of the extruder on broke off, so I glued part of it to the top center of the handle. You can also see that with that mod installed the x gantry sits very level. Now it's not 100% level, but within a couple degrees by a pretty good guess. I just used a regular bubble style level.

One of my early prints, it curled up a bit, I am in need of heating it up to flatten it out and paint it, and print the feet for it. It's for my girlfriend. You can see all the bad parts of it but for the most part it's pretty decent.

This is actually exactly how it's setup now except it has the heated bed installed. No shot of that yet. Also, because of the windows problem I decided to go headless and install an lcd with an sd card reader on it. That gave me a great reason to flash a new firmware set to the arduino mega board, calibrate to near perfection.

Here are some things I have printed for fun and calibration. So from what I can show its not doing too bad. I still have some things I want to print for it and reprint. I really want to print a box to enclose the electronics with the power all in one.

That's it for now. More to come soon once the work area had come together 100%