Yep, sure do, at least for the family cars. I've got two Craftsman tool chests and matching set of drawers for each. I should take a couple more pictures of the garage once I get it cleaned out, I've got a regular workshop going out there now what with the multiple table saws and such.

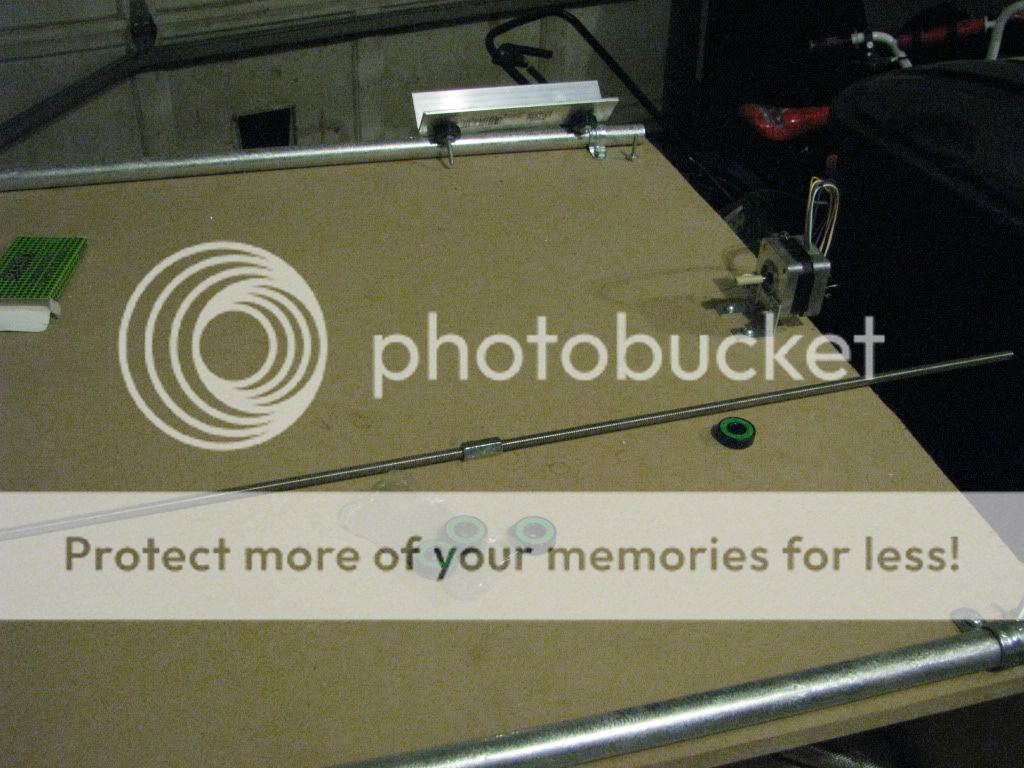

My wife is lovingly indulgent in my various hobbies, which are woefully plentiful. Woodworking, sadly, is not something I'm wonderful at, mainly because this CNC machine is the first real woodworking project I've done... ever.

My wife is lovingly indulgent in my various hobbies, which are woefully plentiful. Woodworking, sadly, is not something I'm wonderful at, mainly because this CNC machine is the first real woodworking project I've done... ever.