rebreok

Member

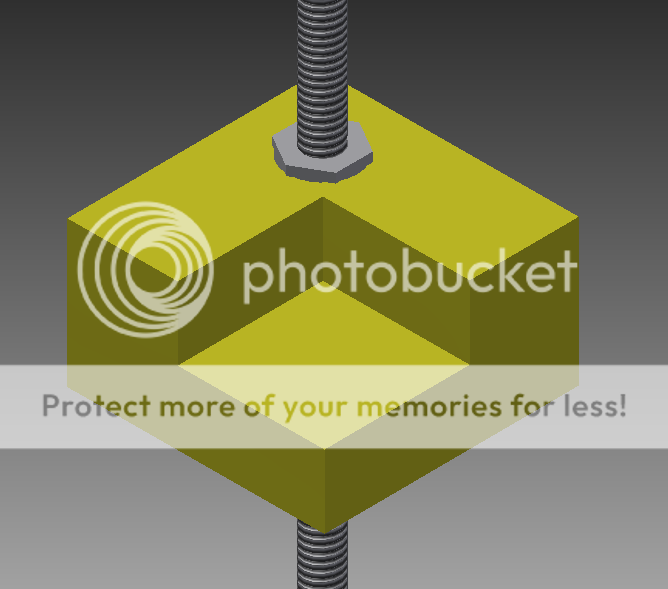

Hi all. I've been working recently on a couple different projects and keep hitting much the same roadblock for each one, which is manufacturing troubles. Because of this, I have decided that the project I must complete before any other will be a 3D printer.

I have a couple of prototypes going already, and I'm working with some college buddies on programming the microcontroller. It's still in the early phases right now, but I think it'll really pick up and go once everyone starts pitching in.

The goal here is actually to produce a 3D printer design which can be easily replicated in any home with the most basic tools and a shoestring budget. With the help of Modretro however, I intend to create a design that is an easy, cheap, and fast build, that quickly evolves itself into a high-quality printer of modular size. Secondarily, I intend to open mine to the public, selling parts for nothing more than technical costs and making a donation-based profit, if any.

The way it would work is there would be a single devoted thread, where the main team (I) post the prototype specifications, needed changes, and existing code, along with any suggestions, observations, etc. Then anyone who wants can work from the existing, post their data, or even complete divergences from the existing path. It matters little just how we do it, I just want to see it done!

If you think this is a good idea, or better yet if you'd like to help, leave a reply and any thoughts.

Looking forward to working to together,

K

I have a couple of prototypes going already, and I'm working with some college buddies on programming the microcontroller. It's still in the early phases right now, but I think it'll really pick up and go once everyone starts pitching in.

The goal here is actually to produce a 3D printer design which can be easily replicated in any home with the most basic tools and a shoestring budget. With the help of Modretro however, I intend to create a design that is an easy, cheap, and fast build, that quickly evolves itself into a high-quality printer of modular size. Secondarily, I intend to open mine to the public, selling parts for nothing more than technical costs and making a donation-based profit, if any.

The way it would work is there would be a single devoted thread, where the main team (I) post the prototype specifications, needed changes, and existing code, along with any suggestions, observations, etc. Then anyone who wants can work from the existing, post their data, or even complete divergences from the existing path. It matters little just how we do it, I just want to see it done!

If you think this is a good idea, or better yet if you'd like to help, leave a reply and any thoughts.

Looking forward to working to together,

K