RedmagnusX

Active Member

Hey Everyone,

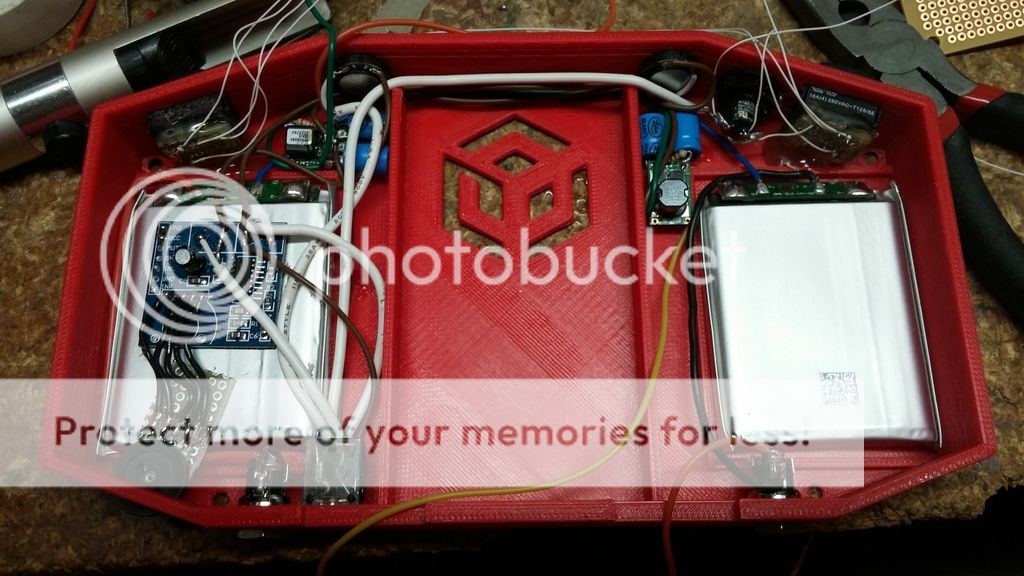

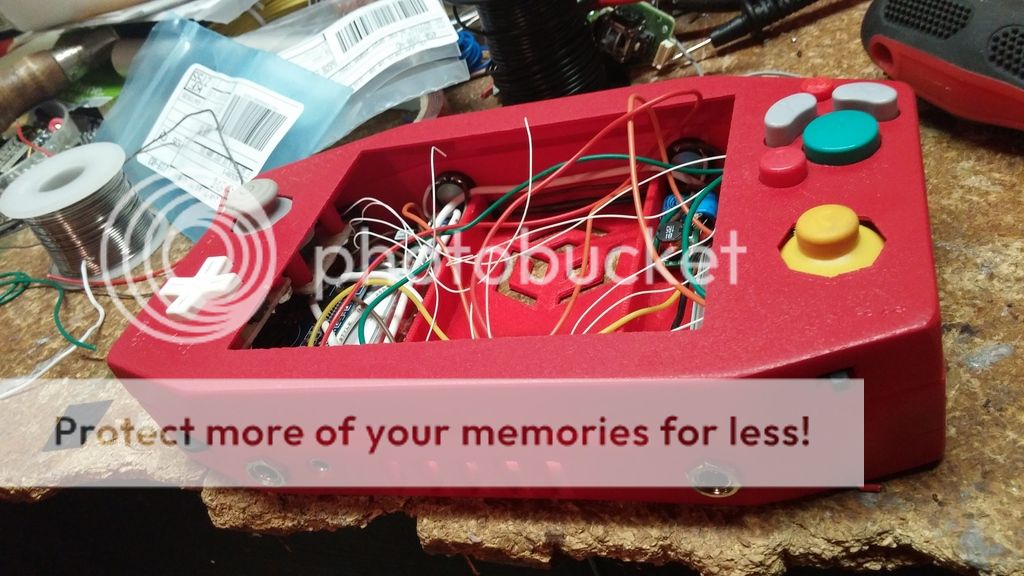

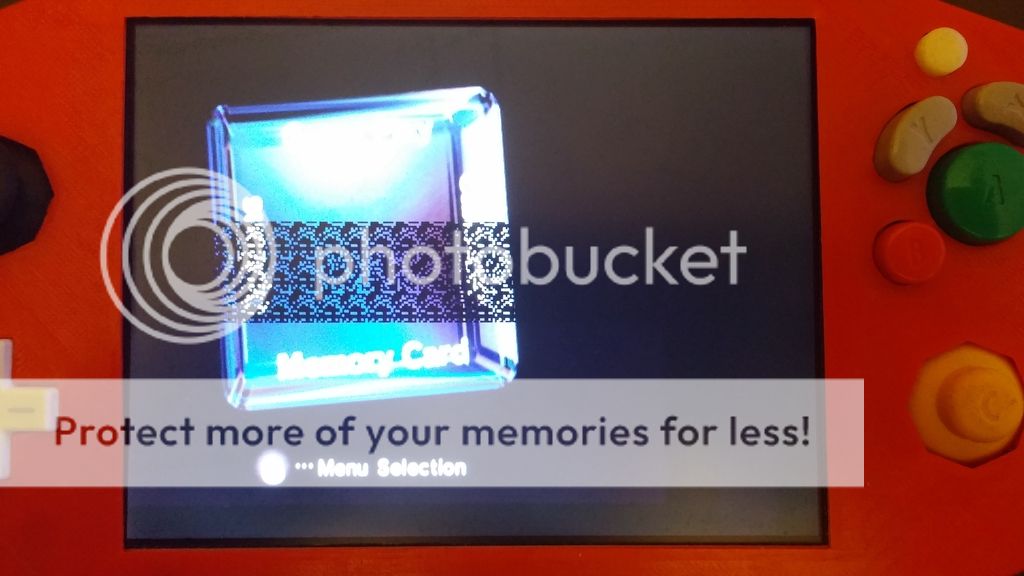

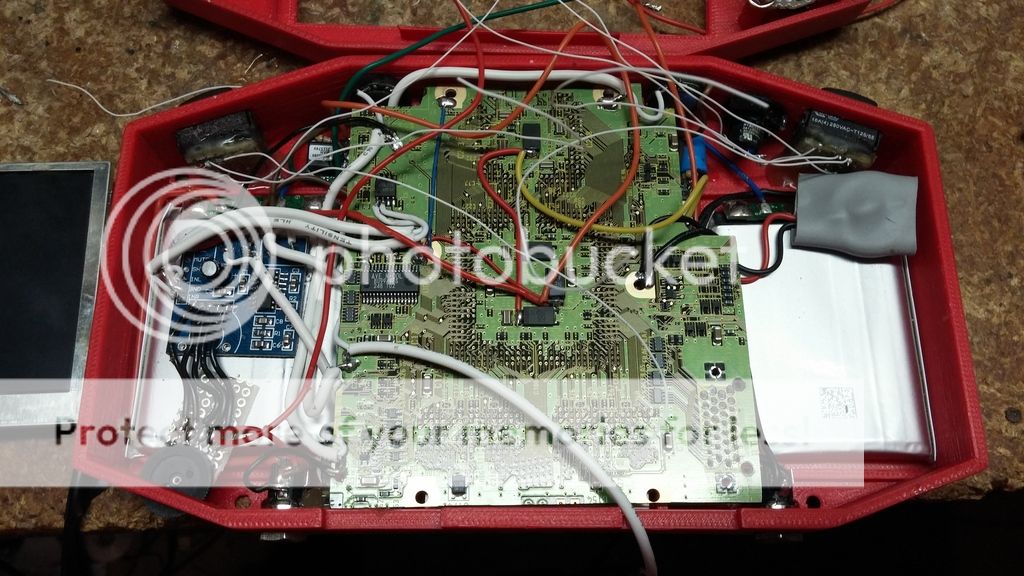

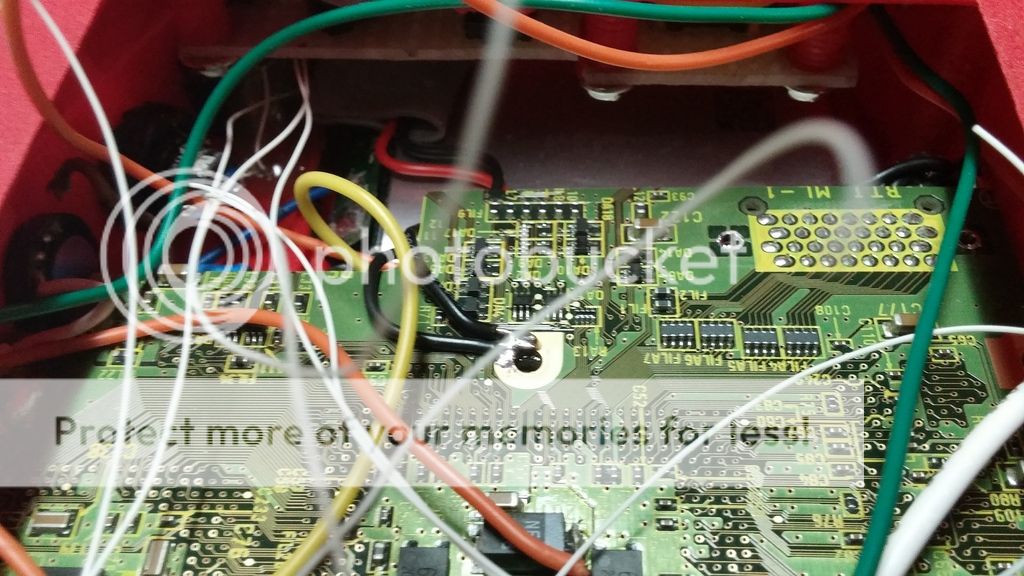

I figured it was about time that I made a proper work log for one of my portable Cubes. This one was commissioned by Portable-Junkie here on the forums. I figured a work log would be a good way to keep him in the know as to how I'm progressing as well as to be a potential source of knowledge for those who may be just starting out who want to tackle the Gamecube themselves.

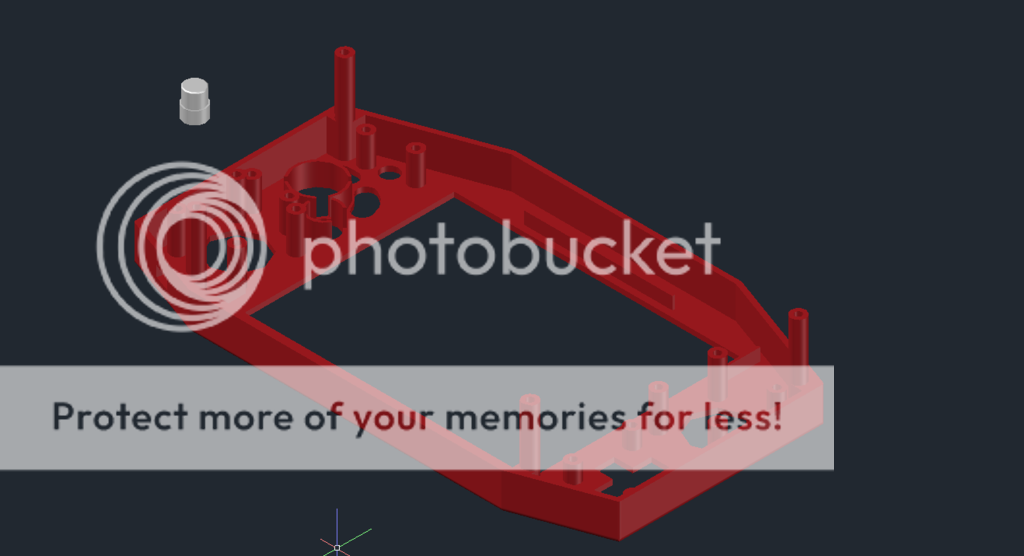

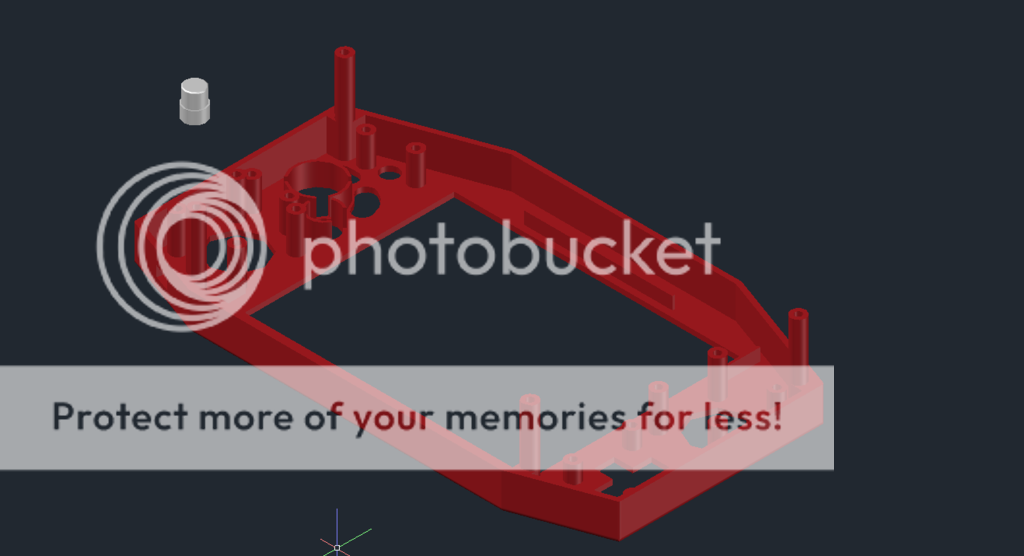

This portable will share the design of the Crimson Cube v2, effectively making it the Crimson Cube v3. Here's some 3d renders of the design from AutoCad.

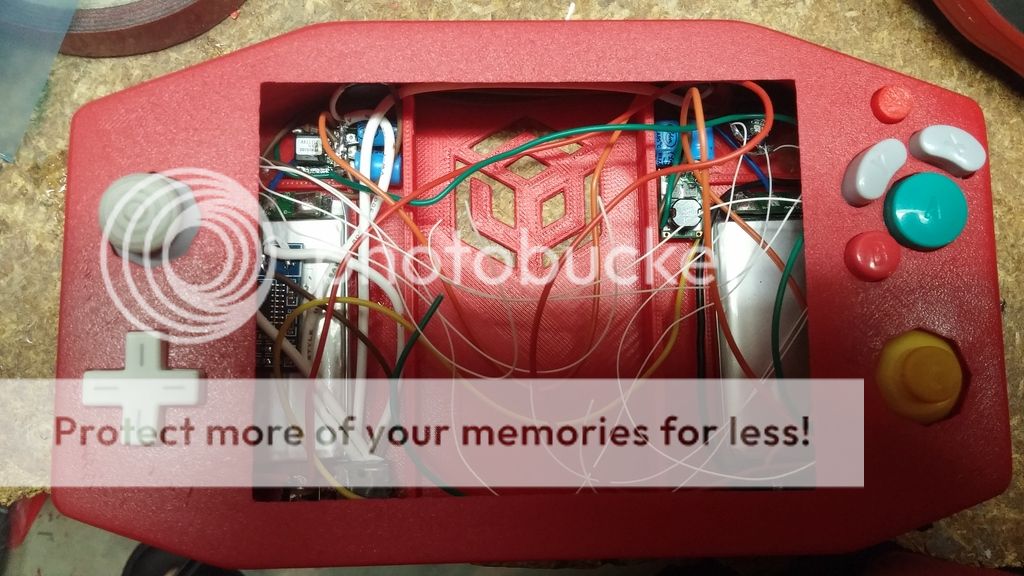

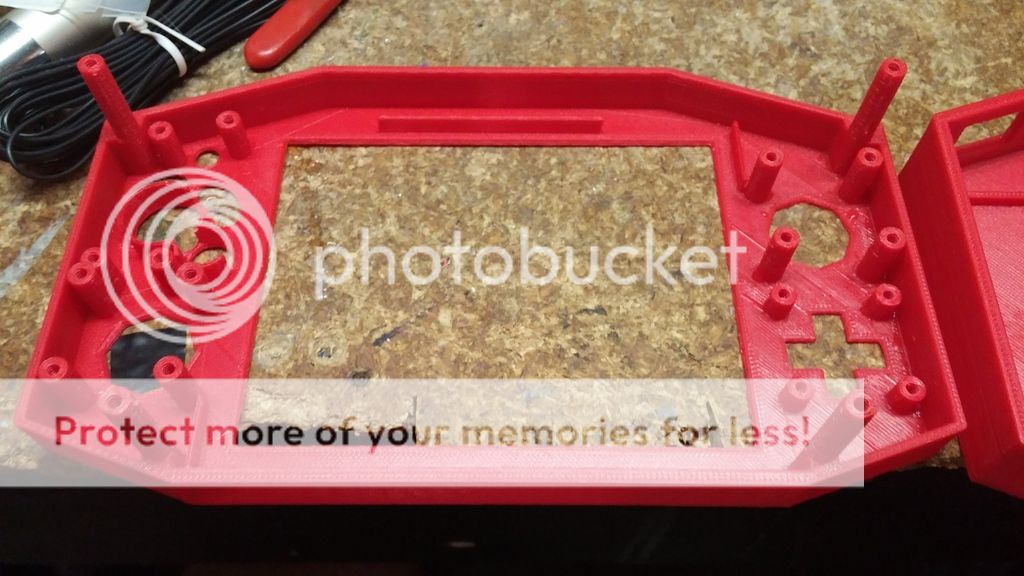

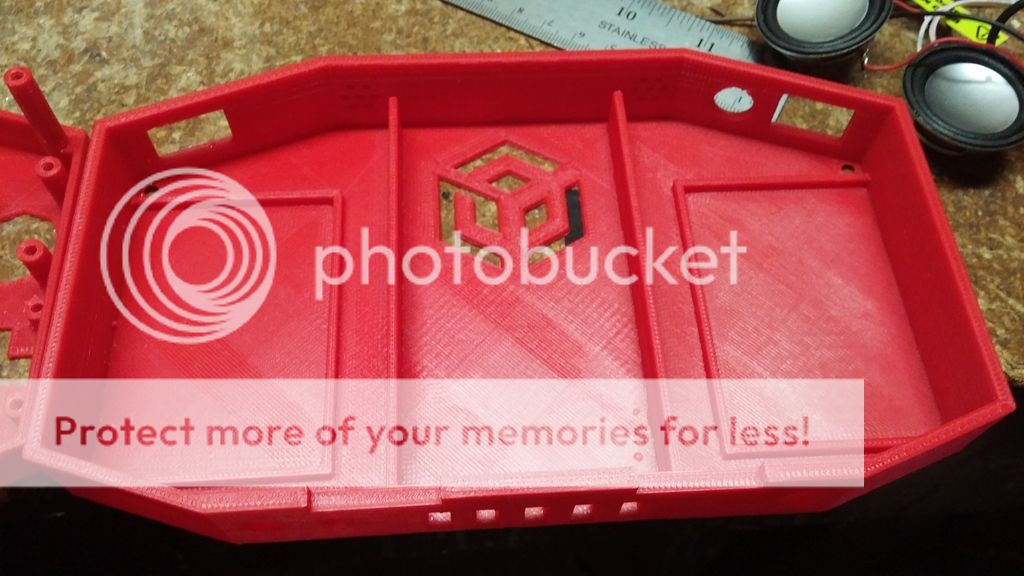

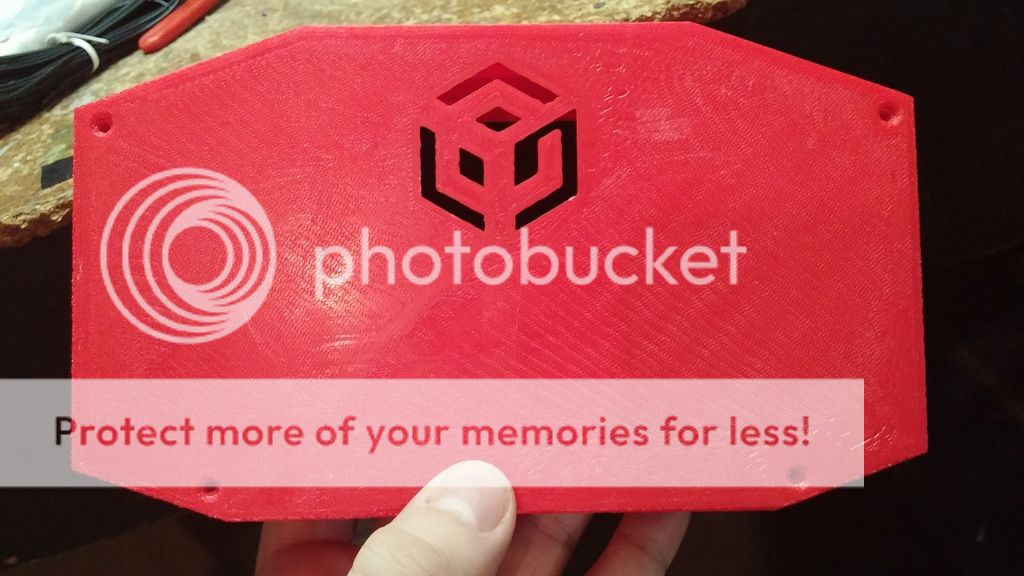

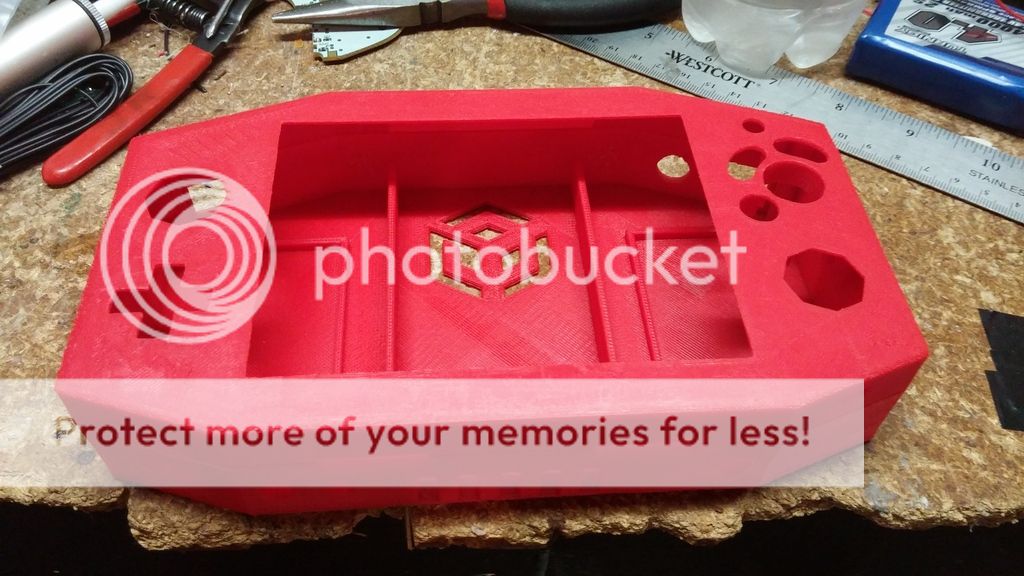

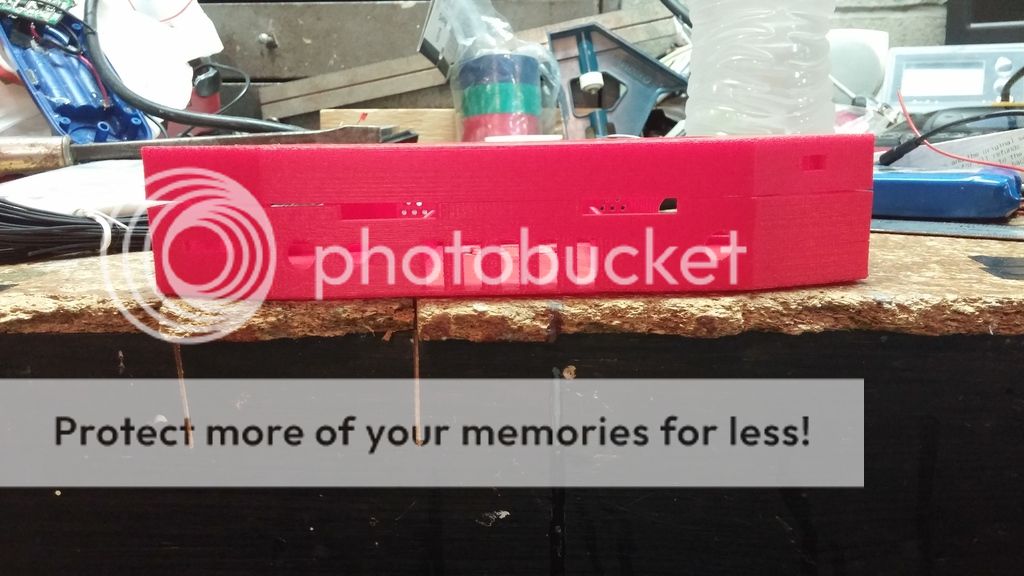

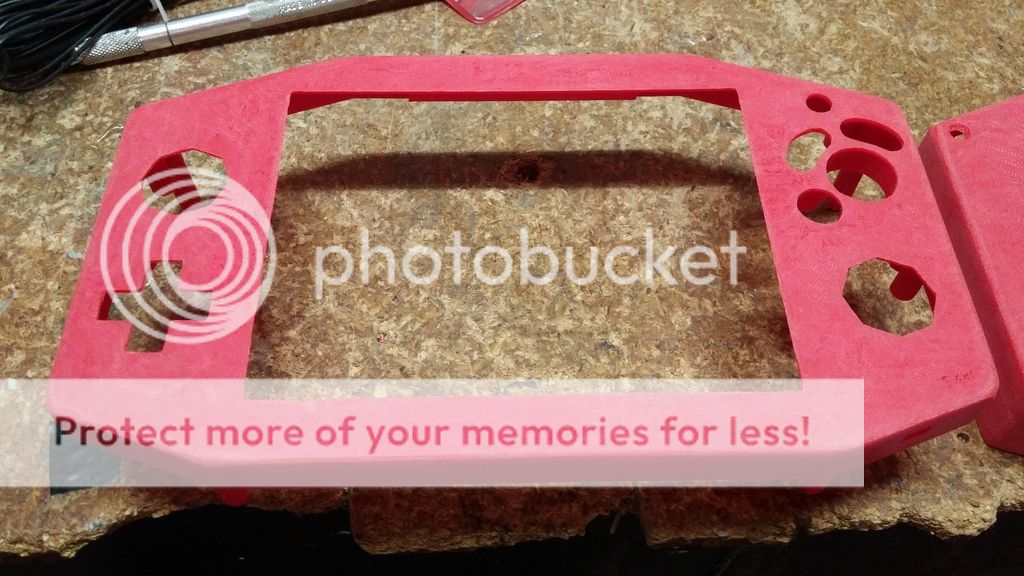

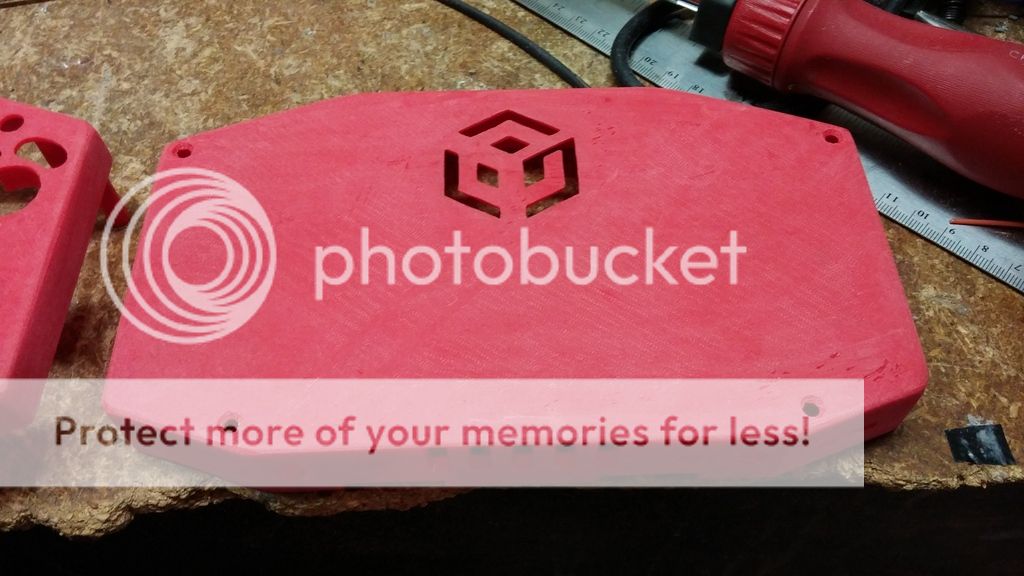

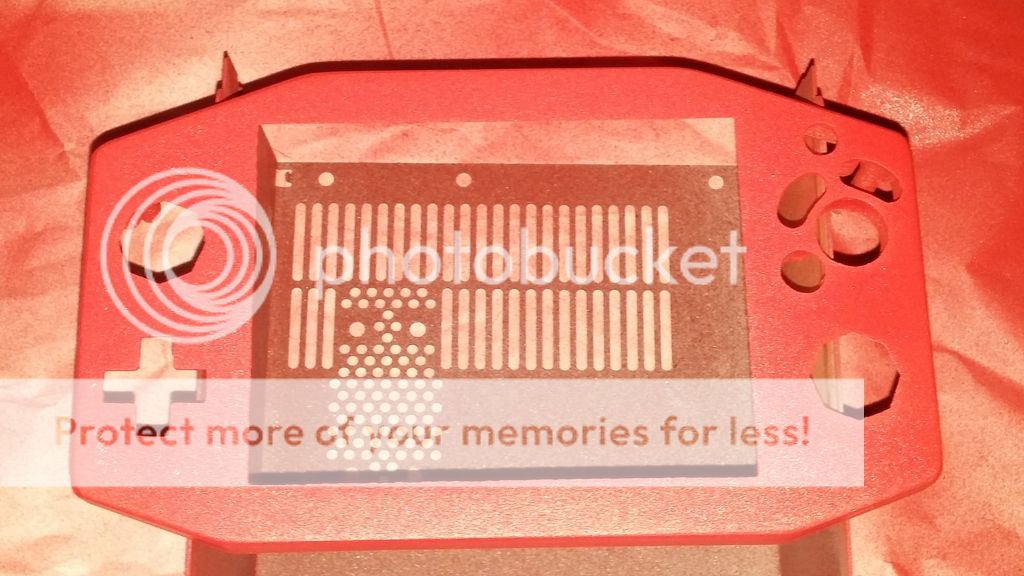

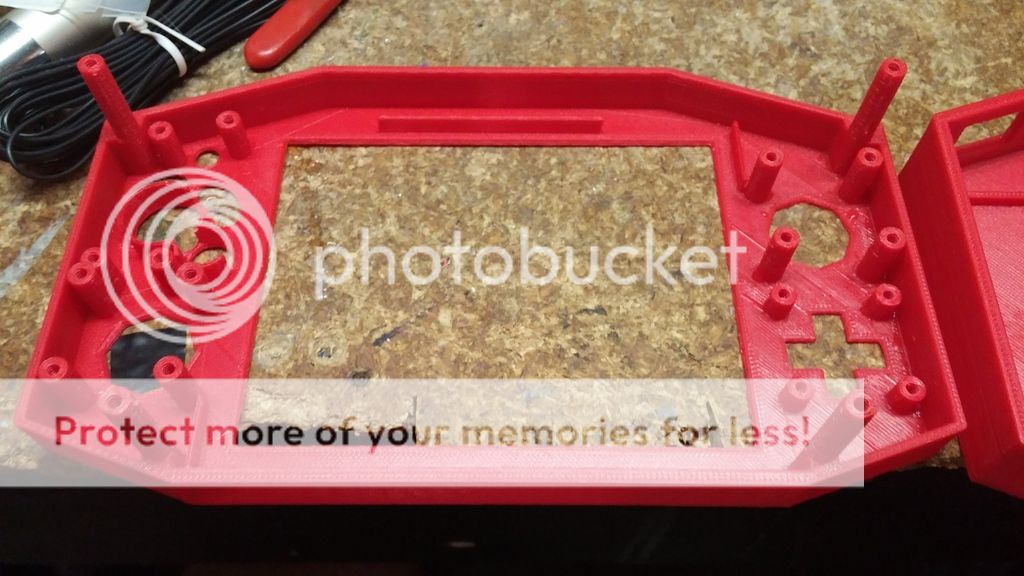

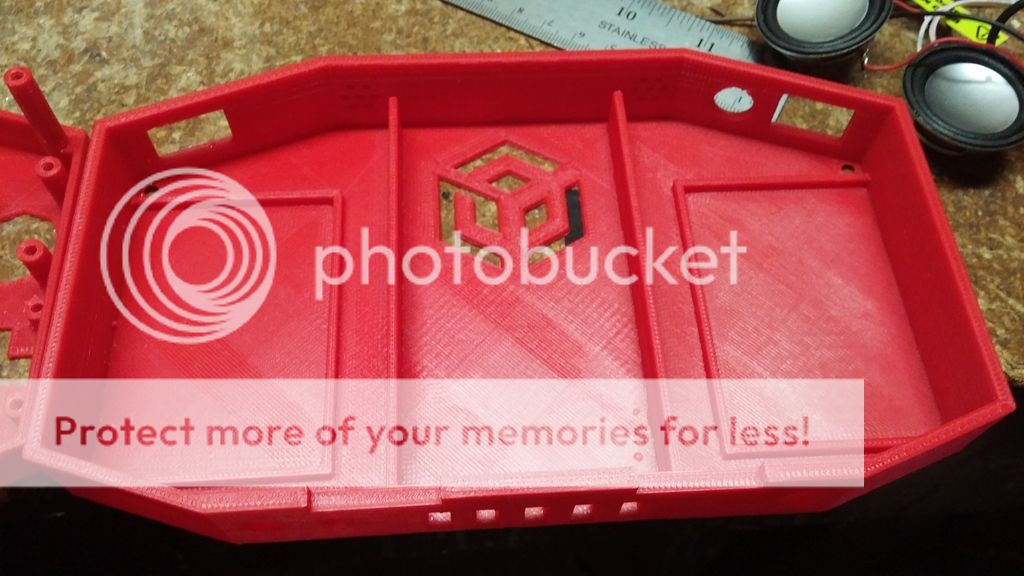

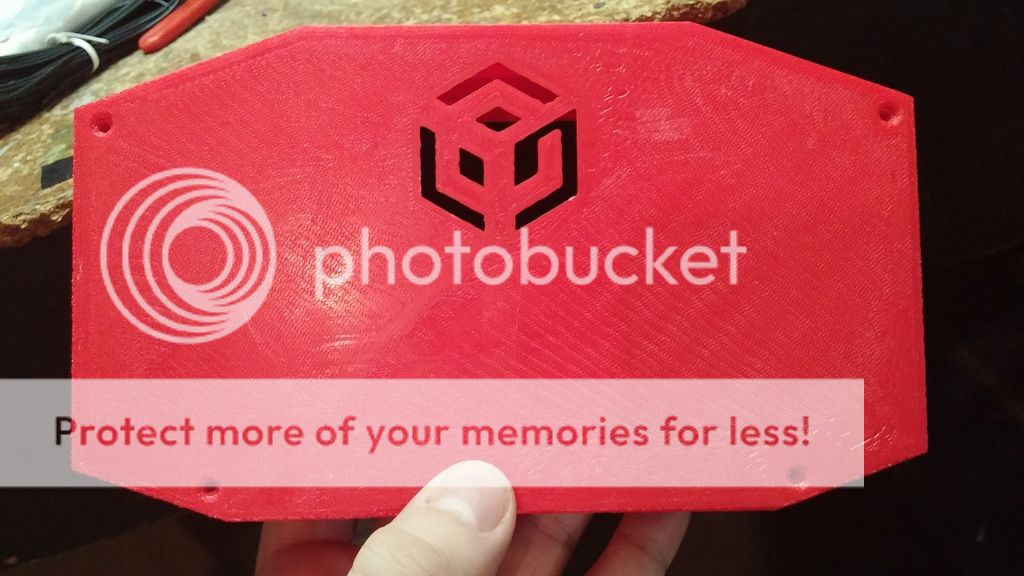

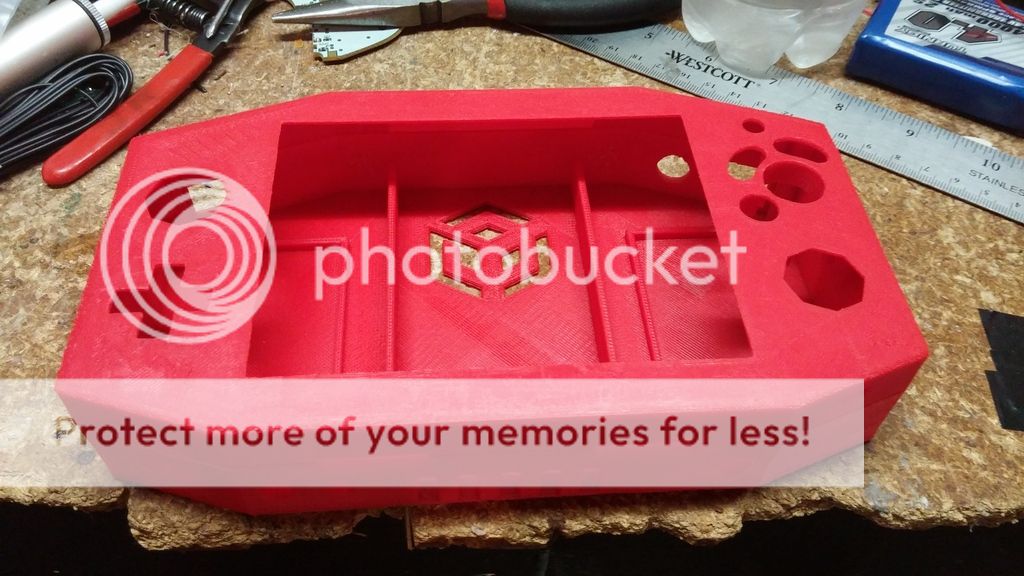

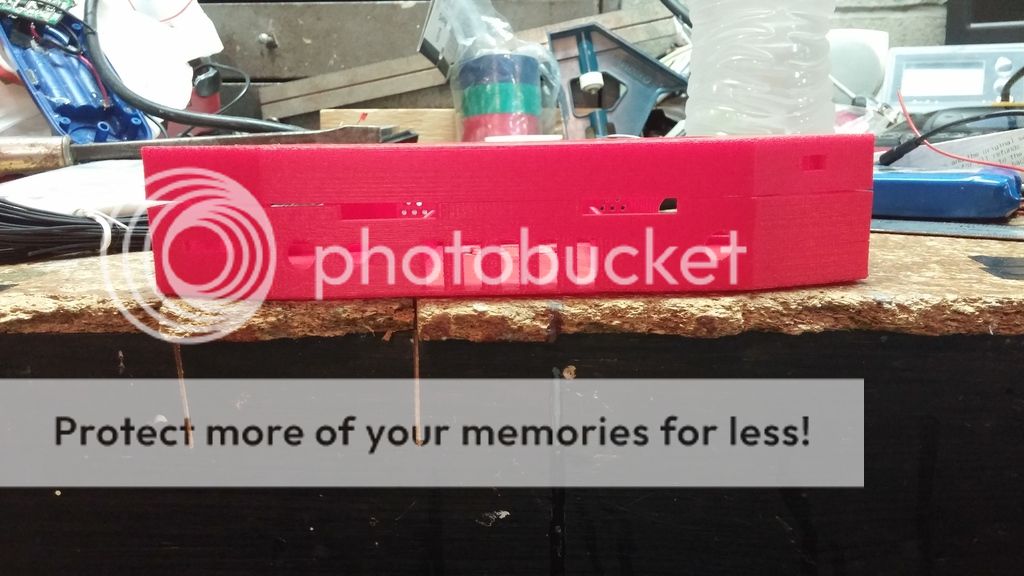

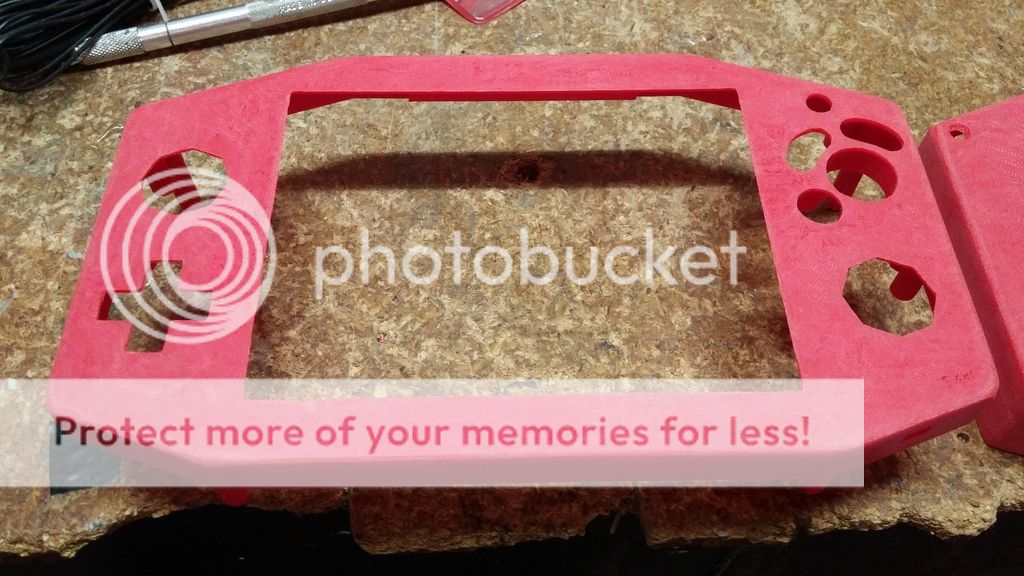

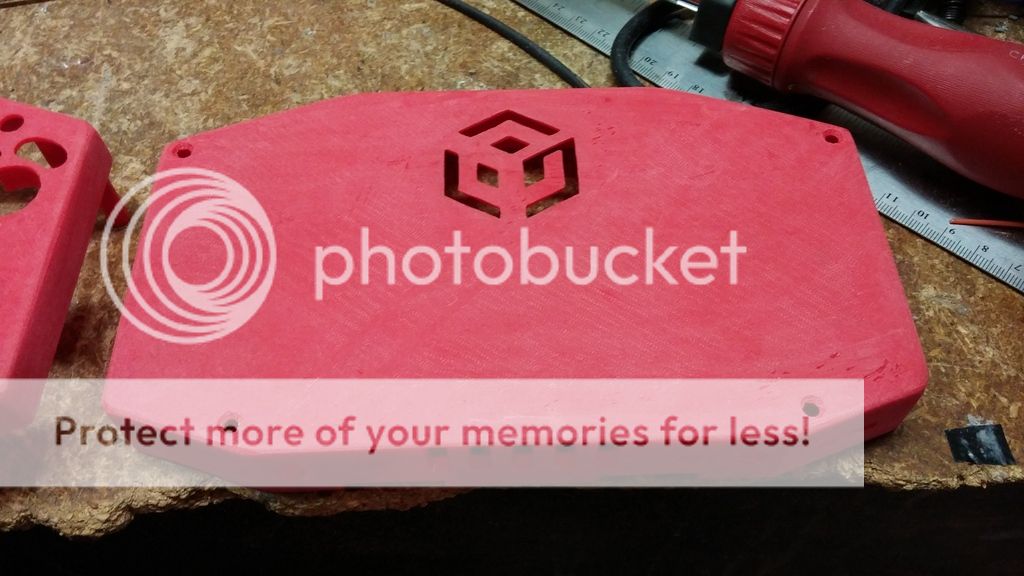

My next step was to print out the design via 3d printer. The pictures below are of the case fresh off the printer.

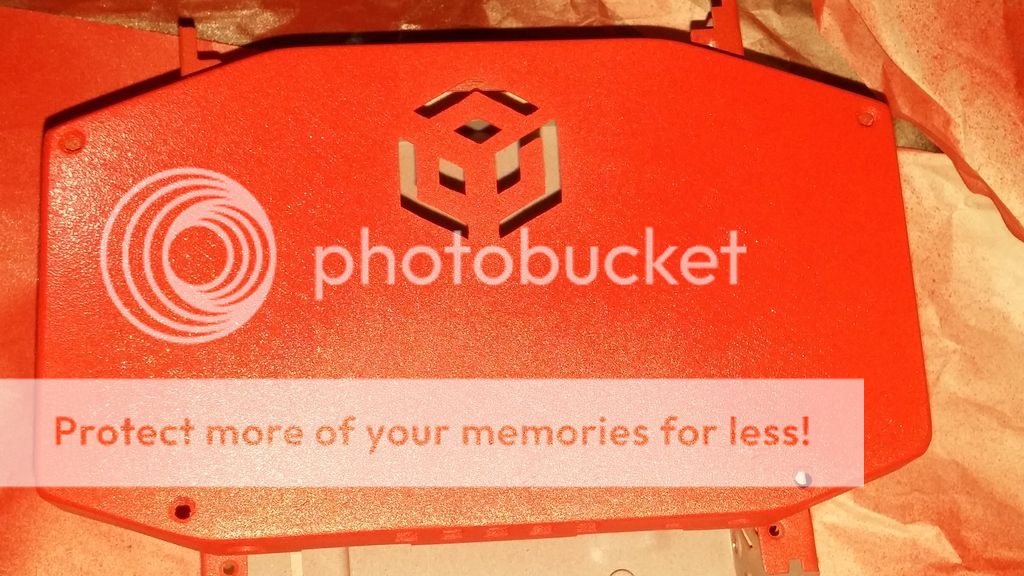

After showing the pictures of the raw printout to my client, he questioned the color of the shell. In order to make sure he was happy with the result, I opted to paint it a deeper shade of Red. So the pictures below are of the shell after the prep and paint process.

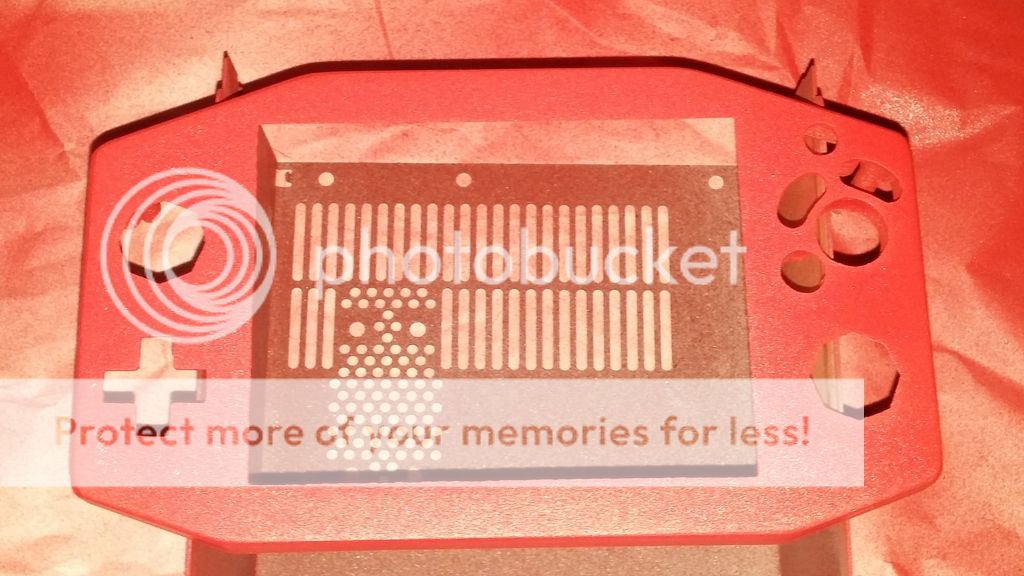

Sanded and Ready for paint:

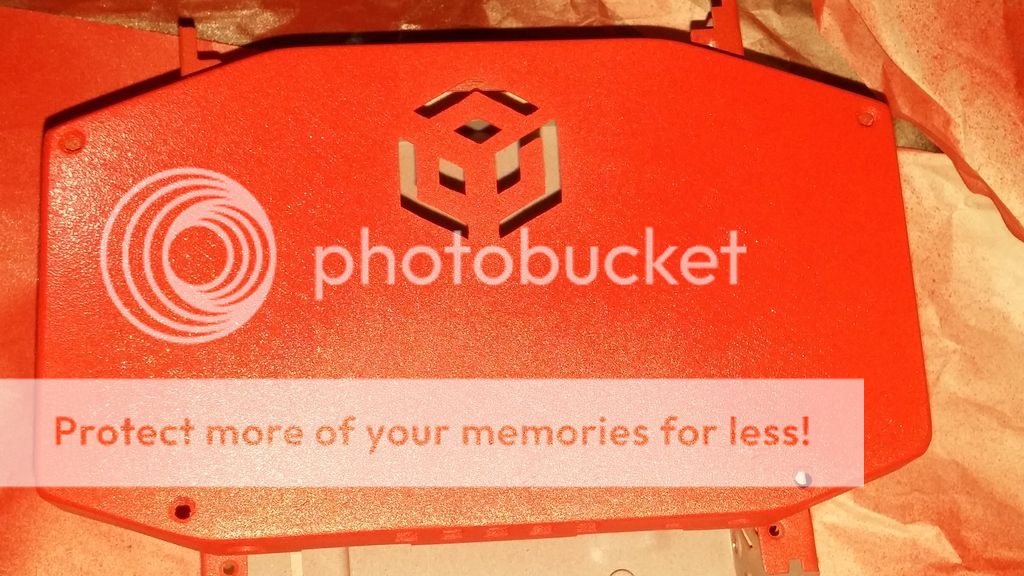

Painted:

The pictures don't really do the color justice. It's a darker red than the pictures would suggest. That's all I have for now. I will post updates following next week since I'll be on vacation this week.

I figured it was about time that I made a proper work log for one of my portable Cubes. This one was commissioned by Portable-Junkie here on the forums. I figured a work log would be a good way to keep him in the know as to how I'm progressing as well as to be a potential source of knowledge for those who may be just starting out who want to tackle the Gamecube themselves.

This portable will share the design of the Crimson Cube v2, effectively making it the Crimson Cube v3. Here's some 3d renders of the design from AutoCad.

My next step was to print out the design via 3d printer. The pictures below are of the case fresh off the printer.

After showing the pictures of the raw printout to my client, he questioned the color of the shell. In order to make sure he was happy with the result, I opted to paint it a deeper shade of Red. So the pictures below are of the shell after the prep and paint process.

Sanded and Ready for paint:

Painted:

The pictures don't really do the color justice. It's a darker red than the pictures would suggest. That's all I have for now. I will post updates following next week since I'll be on vacation this week.